Jim Guess, P.E.

Drone LiDAR for Distribution Design:

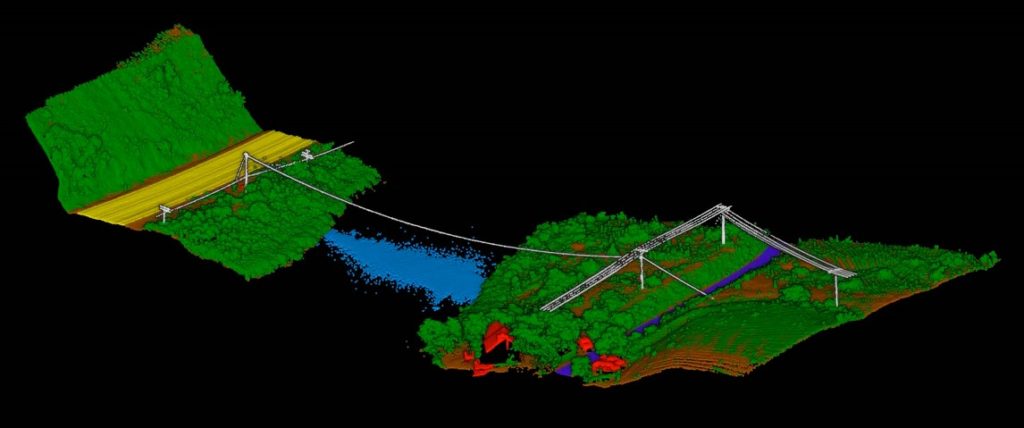

Thanks to the continued advancements in Unmanned Aerial Vehicle (UAV) technology, our industry is seeing more and more applications where utilizing a drone is a cost-effective solution for current utility needs. Drones have been utilized in our industry for everything from line patrol to line inspection with good results. The advancement in drone technology coupled with the dropping cost of LiDAR equipment has made utilizing a drone for LiDAR a cost-effective tool for gathering the information needed for the design of overhead powerlines. And while LiDAR capability has been available to our industry for many years, the more traditional LiDAR flown by a fixed wing aircraft has typically been reserved for larger projects. Drone LiDAR has shown itself to be well suited for small to medium sized projects. Once you get into larger projects the fixed wing LiDAR will likely be of better value due to the multiple set-ups required for the drone operator to cover long distances.

The value of obtaining LiDAR data versus data collected via more traditional methods is being realized more and more as we are constantly dealing with tighter clearance windows and other constraints from continued development. LiDAR data is especially valuable as the detailed design of overhead powerlines continues to move towards three-dimensional design software, like PLS-CADD.

PLS-CADD and PLS-Distribution:

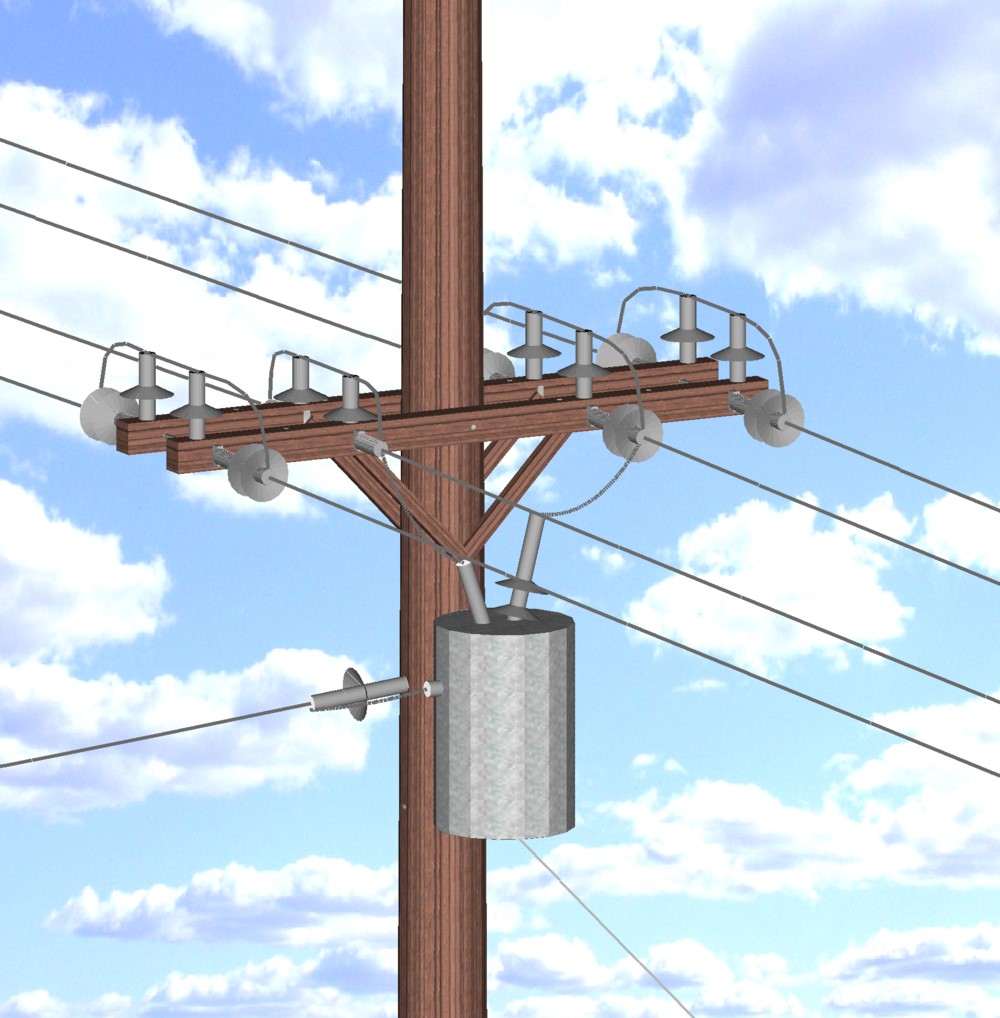

PLS-CADD is known for providing very powerful and comprehensive overhead powerline design and drafting software. Recently PLS has announced the release of PLS-Distribution. This is a new software release that provides a more streamlined user interface that once coupled with utility standards, can allow for the efficient use of PLS-CADD as a design tool for distribution teams. PLS-Distribution still utilizes the same powerful engine that PLS-CADD uses with certain changes made to the menu and to include more distribution terminology and many of the advanced features removed to simplify the software.

For more information please visit https://www.powerlinesystems.com/pls-distribution

ASCE Manual of Practice 141: Wood Pole Structures

The American Society of Civil Engineers (ASCE) has released a new manual of practice (MOP) for the design and use of wood poles for electrical transmission lines. Although this MOP is geared towards transmission lines, many of the topics covered are applicable to the design of overhead distribution lines as well. And as reliability and resiliency become even more important for overhead power lines, this MOP can provide valuable insight on many different topics that impact the performance of overhead power lines utilizing wood poles. The new MOP covers many topics such as wood pole design, connections, foundation and anchoring, manufacturing and inspection among others.

Content Highlight, Wood Pole Foundations: Wood poles are typically directly embedded into the soil. In this case a portion of the pole is buried below grade providing stability for the structure and the lines it supports. The rule-of-thumb that many in the industry have adopted is to embed the pole to a depth of 10% of the pole length plus two feet. While this rule-of-thumb works in many cases for overhead distribution, the line designer should be aware that there are limitations to this approach. Chapter 6 of ASCE MOP 141 states “Several studies evaluating the rule-of-thumb method have shown that in many cases, this method does not provide adequate embedment depth for heavily loaded poles or certain soil conditions (For more information on wood pole bury depths in various soils, see Lutein 2009)”. Foundation failure isn’t necessarily a catastrophic failure, it may be that a pole is starting to lean excessively due to the soils not being able to adequately support the structure loads. There are multiple methods available that can be used to determine the suitability of the soil for the determined structure loading. One thing that may be required is soil testing and a geotechnical analysis. Understanding the local conditions and soil characteristics coupled with the design structure loads allows the line designer to select the appropriate embedment depth for the structure.

The new ASCE MOP 141 can be purchased under the foll

ASCE Manual of Practice 141: Wood Pole Structures

The American Society of Civil Engineers (ASCE) has released a new manual of practice (MOP) for the design and use of wood poles for electrical transmission lines. Although this MOP is geared towards transmission lines, many of the topics covered are applicable to the design of overhead distribution lines as well. And as reliability and resiliency become even more important for overhead power lines, this MOP can provide valuable insight on many different topics that impact the performance of overhead power lines utilizing wood poles. The new MOP covers many topics such as wood pole design, connections, foundation and anchoring, manufacturing and inspection among others.

Content Highlight, Wood Pole Foundations: Wood poles are typically directly embedded into the soil. In this case, a portion of the pole is buried below grade providing stability for the structure and the lines it supports. The rule-of-thumb that many in the industry have adopted is to embed the pole to a depth of 10% of the pole length plus two feet. While this rule-of-thumb works in many cases for overhead distribution, the line designer should be aware that there are limitations to this approach. Chapter 6 of ASCE MOP 141 states “Several studies evaluating the rule-of-thumb method have shown that in many cases, this method does not provide adequate embedment depth for heavily loaded poles or certain soil conditions (For more information on wood pole bury depths in various soils, see Lutein 2009)”.

Foundation failure isn’t necessarily a catastrophic failure, it may be that a pole is starting to lean excessively due to the soils not being able to adequately support the structure loads. There are multiple methods available that can be used to determine the suitability of the soil for the determined structure loading. One thing that may be required is soil testing and a geotechnical analysis. Understanding the local conditions and soil characteristics coupled with the design structure loads allows the line designer to select the appropriate embedment depth for the structure.

The new ASCE MOP 141 can be purchased under the following link: https://webstore.ansi.org/standards/asce/ascemop1412019

ng link: https://webstore.ansi.org/standards/asce/ascemop1412019